You can attach mechanical loads sensors or motion controllers to the motor through this pin. Adherence to the HE sensor was for simplicity and to reinforce the magnetic field aspects of the machine operation.

Dc Machine Construction 1 Pole Pieces 2 Steel Yoke 3 Commutator 4 Conductors In Slots 5 Carbon Carbon Brushes High Technology Knowledge

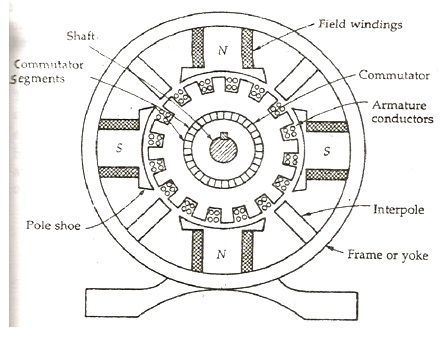

A DC machine consists of two basic parts.

. ωm Speed in radians. Often know as the field. Consider the drawing and illustration.

The common feature and the essential condition of all DC motors is the generation of a variable magnetic field that provides their non. As in power generation system and industries mostly ac machines like an induction motor synchronous motor generators are employed but the use of dc machines cannot be denied due to its constant speed providing the capability. The diagram given below represents the various parts of a DC machine.

It not only provides mechanical strength to the. 1- Field magnetic poles 2- Armature. Many modern DC machines are constructed with a permanent magnet PM field which results in a constant flux.

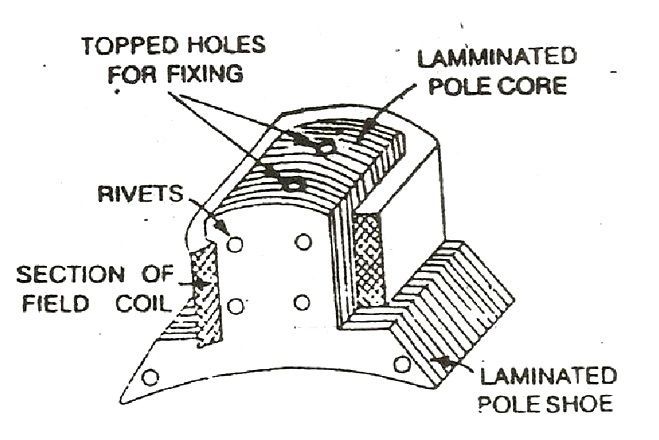

As an open loop system the field control method is ideal for operators who need cost-effectiveness smooth performance and steady. Height of the pole is calculated based on the height of the filed coil required and the insulation. Find the main dimensions of the machine if it has to.

Magnetic field system armature and commutator and brush gear. Series Wound DC Machine. Doing so intentionally and as necessary requires speed control.

All these parts put together make up the total construction of a DC motor. A direct current DC motor is the oldest type of electrical motor that has gained widespread use in a variety of electronic devices and equipment. Many applications require a DC motors speed to adjust maximizing machine function and performance.

Pole Coils or Field Coils. If Field current. Laf Armature-field mutual inductance.

Vt Terminal voltage applied to the machine. Determine Lmtof field coil Assume suitable depth of field winding For rectangular coils Lmt 2 Lp bp 2df or Lo Li2 For cylindrical coils Lmt π dp df Step 3. Of dc motor using state space approach.

Though the losses are more DC machines find its importance in modern day to day life. Ea Back-EMF voltage. The mechanical switching is acheived using a device called a split-ring commutator.

In a PM DC machine the armature circuit model is the complete circuit model and k ϕ is constant. Basic constructional parts of a DC machine are described below. Armature ampere turns per pole ATa 135 Iph Tph Kw p And.

When we evaluate with DC machines Alternating Current machines have more advantages because of the losses that appear in DC. The stator carries a field winding that is used to produce the required magnetic field by DC excitation. A DC machine is used to operate the devices which use unidirectional current.

Ia Armature current. A 5 kW 400 V 4 pole 1500 rpm DC shunt generator has the average flux density in the airgap as 12 Wbm 2 and the specific electric loading is 21000 Am. Traditionally the flux is produced and controlled by a field winding.

The performance of dc motor under various conditions is simulated using MATLABSIMULINK environment and simulation result demonstrates the feasibility of the proposed system. Advantages of Field Controlled DC Motors. Calculate cross section area of filed conductor Af ρLmt ATflEf Step 5.

It is made up of cast iron or steel. Magnetic frame or Yoke. Datasheets often state voltage current and speed values at rated conditions.

Pole Cores and Pole Shoes. DC motors have different arrangements and operation peculiarities. The rotor carries a.

The voltage on this pin represents the mechanical angular speed in rads. Describe the procedure for design of interpoles of DC machine. Positive and negative terminals of armature winding.

Stationary part of the machine. Calculate the voltage across each shunt field coil Ef 08 to 085 VP Step 4. In a DC machine developed before the era of power electronics a mechanical system is used to switch the AC generated loop voltage and give a DC voltage at the terminals of the machine.

The typical DC machine has a stator-mounted field winding which produces. The armature circuit behaviour is dependent on the flux in machine. A DC Generator is an electrical device which converts mechanical energy into electrical energy.

The DC machines are classified into two types such as DC generator as well as DC motor. This component models a brushed DC machine where the field is set by an energized field winding. It has its unique feature of generating unidirectional.

This process is called commutation. This experiment explores all the possible design connections of a DC machine. The outer frame of a dc machine is called as yoke.

Hence full load field ampere turns per pole can be assumed 17 to 20 times the armature ampere turns per pole. The field is the stationary part of. The above figure shows constructional details of a simple 4-pole DC machine.

A stator is the static part of the DC machine that houses the field windings and receives the supply. ATfl 17 to 20 ATa. It mainly consists of three main parts ie.

A rotor is the rotating part of the DC machine that brings about the mechanical rotations. The insulation between the turns of series field depends mainly upon whether the coil is flat-. A state feedback gain matrix is designed for the dc motor with the help of pole-placement technique.

The working principle of a DC machine is when electric current flows through a coil within a magnetic field and then the magnetic force generates a torque that rotates the dc motor. If current in the. Ra Armature resistance.

Describe the procedure for design of field system of DC machine. These values can be used directly in the above expression to solve. The other parts of a DC Generator are magnetic frame and yoke pole core and pole shoes field or exciting coils armature core and windings.

DC Motors and Generators DC motor Fall15 Revised. Height of the filed coil. Machine a torque angle of 90 is the normal condition with field and armature mmfs maintained in quadrature by the angular-position switching action of brushes and commutator.

The rotor is the rotating part of the machine. Thus the system is neutralized by an object of great mass. In these dc machines the field windings are connected with the armature windings in.

In this type of DC machine the field winding is connected in parallel with the armature winding. All dc machines have five principal components. A DC machine is an electromechanical energy alteration device.

3232007 ELEC A6 DC Machine 7 DC MACHINES Real DC machine Construction Stator.

Types Of Dc Generators Diagrams Included Electrical4u

Electricaleasy Com Basic Construction And Working Of A Dc Generator

Construction Of A Dc Generator Explanation Of Its Various Parts Circuit Globe

How To Construct Dc Generator Electronic Circuit Design Circuit Design Electrical Projects

Gramme Ring And Drum Wound Armature In Dc Motors Drums Iron Ring Wind

Construction Of A Dc Generator Explanation Of Its Various Parts Circuit Globe

Types Of Electric Machines Eeeguide Com Electricity Machine Type

Dc Motor Diagram Motor Mechanical Energy Flower Background Design

0 comments

Post a Comment